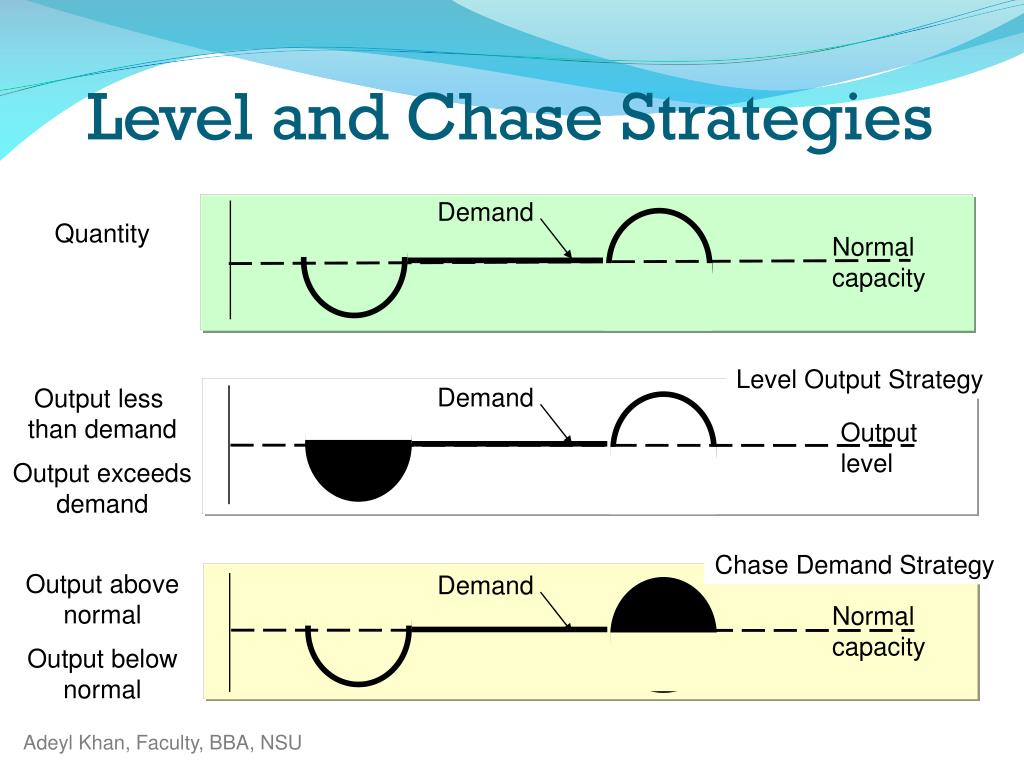

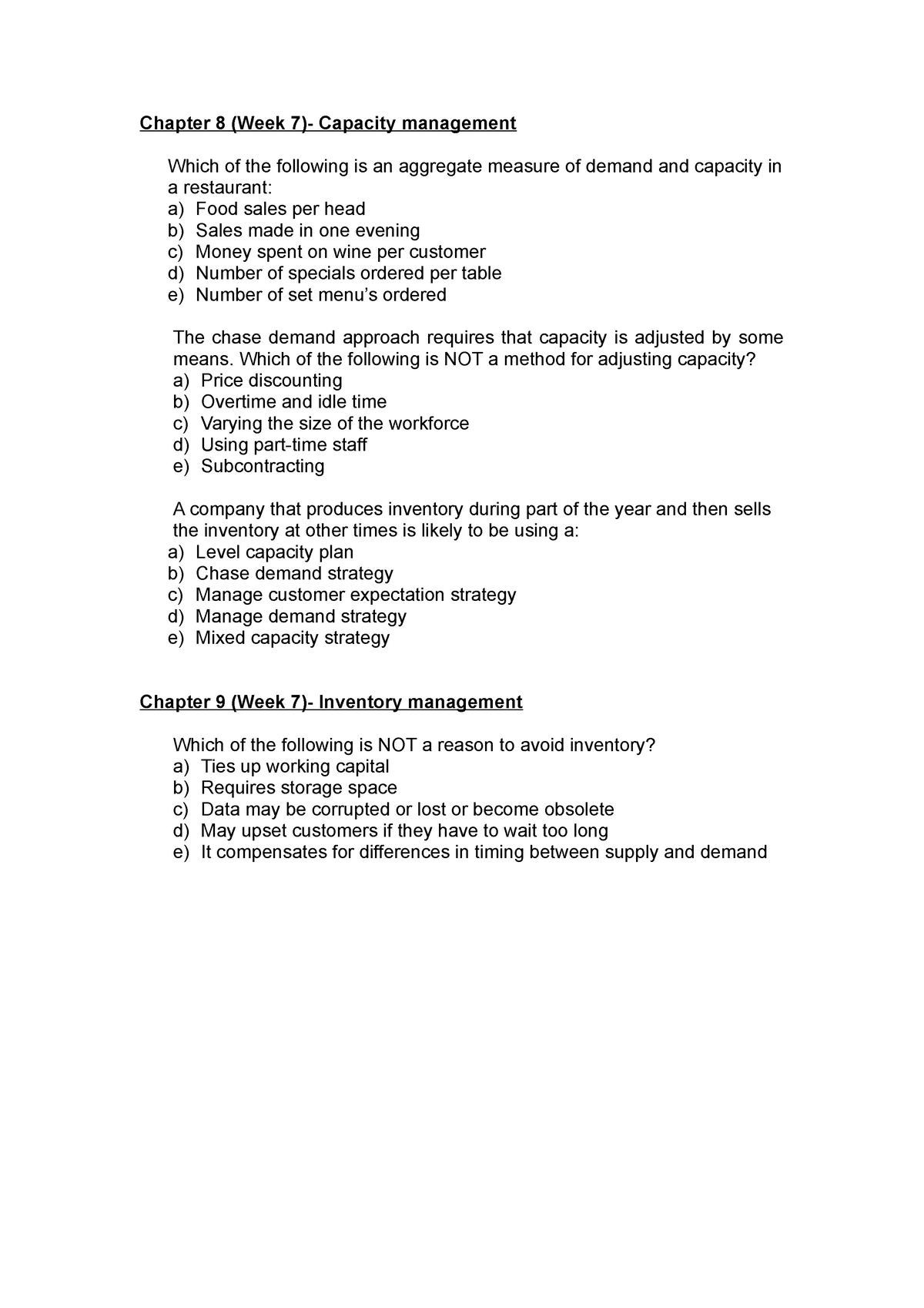

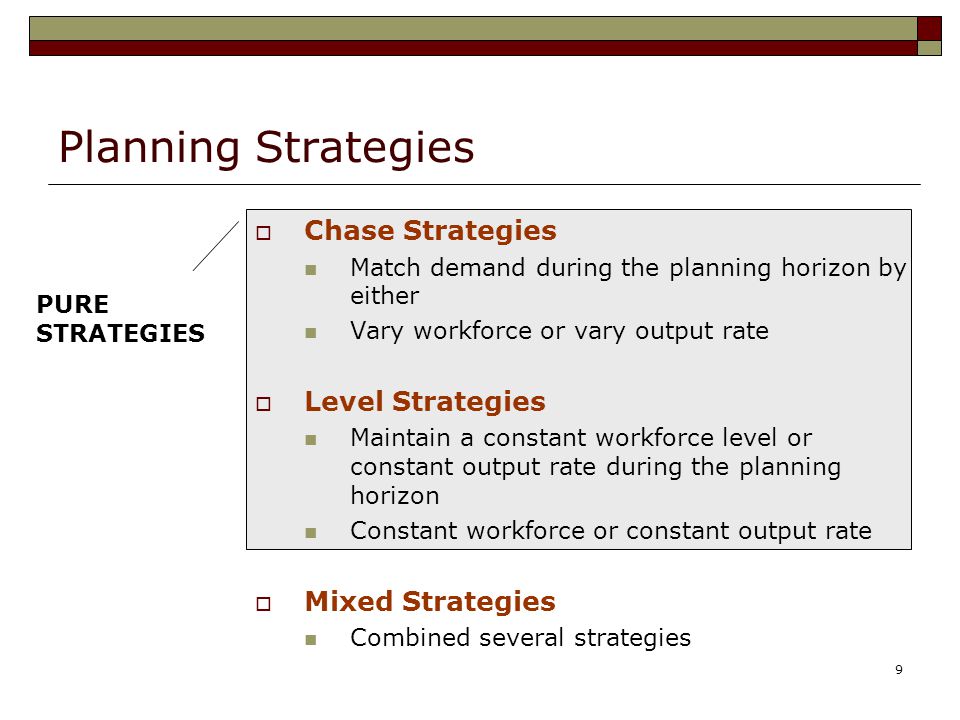

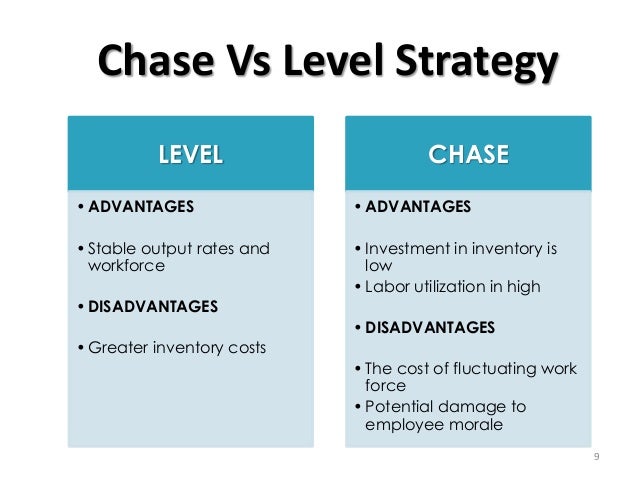

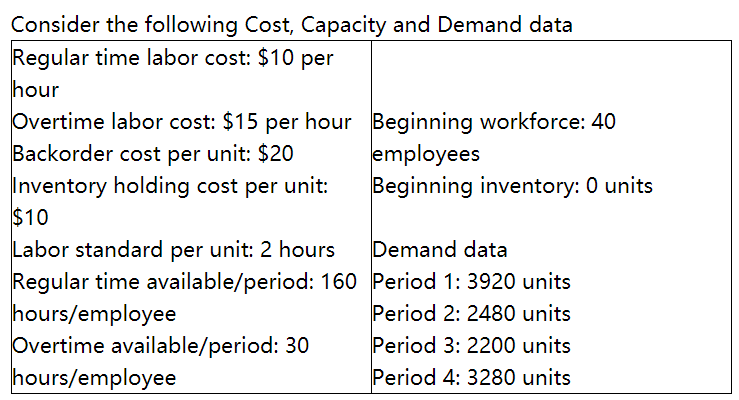

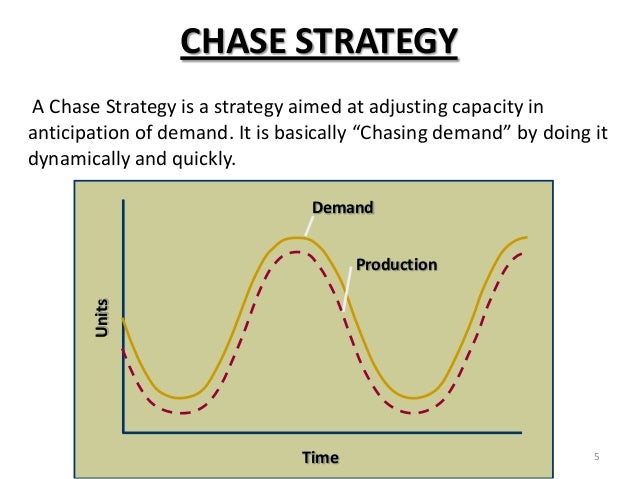

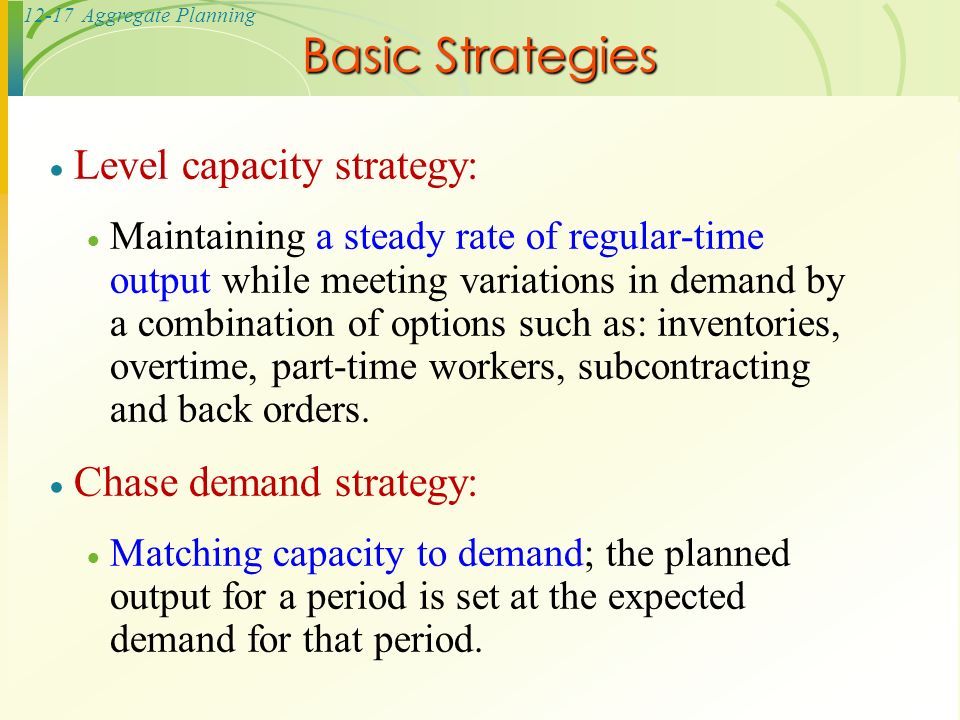

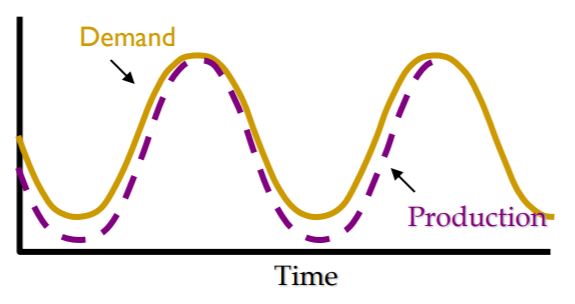

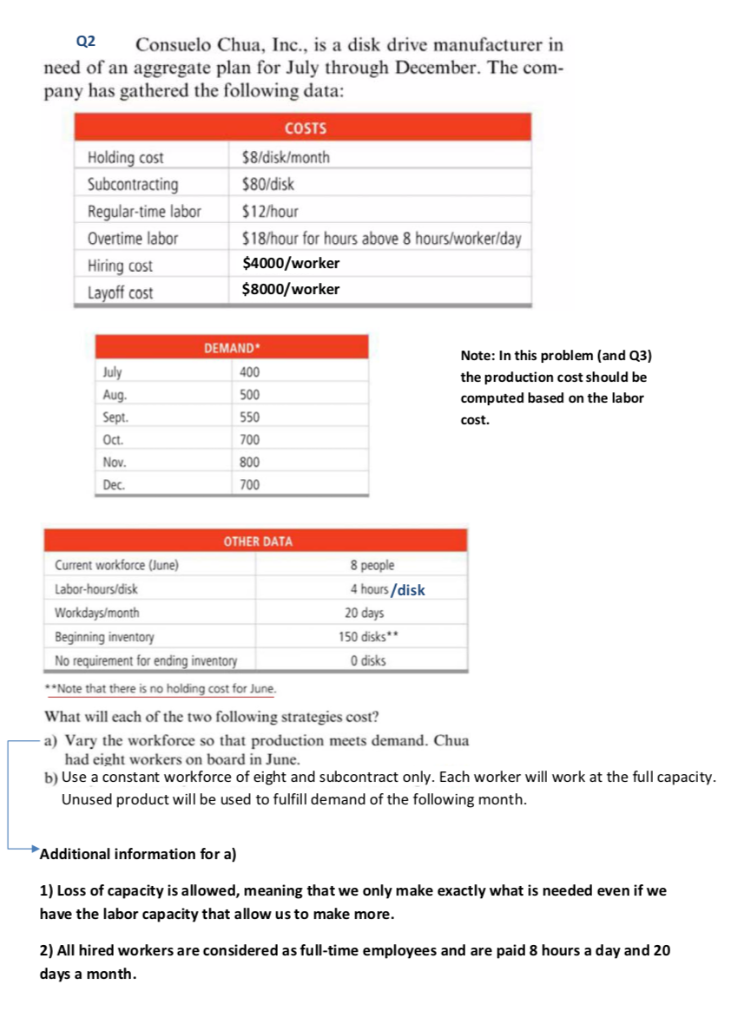

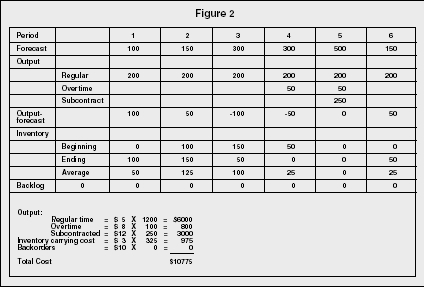

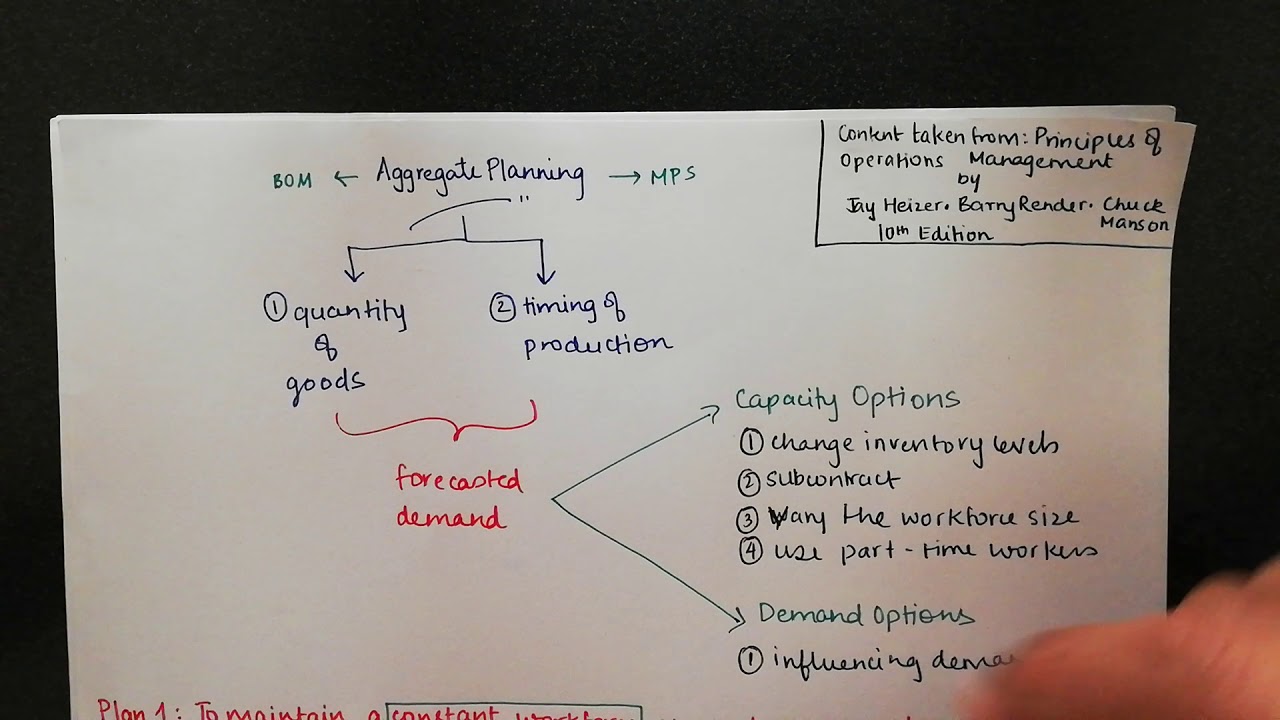

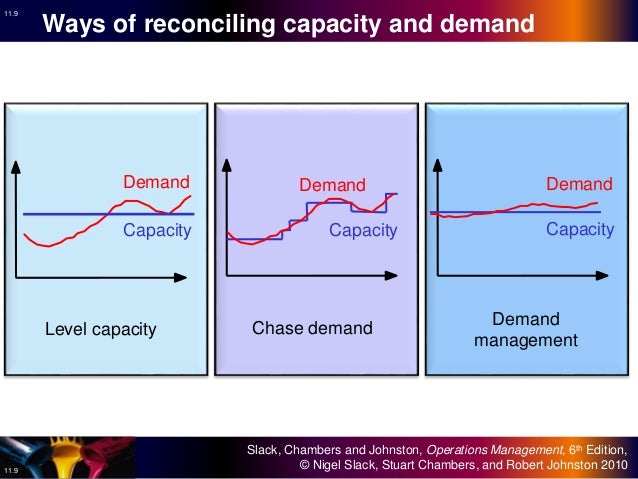

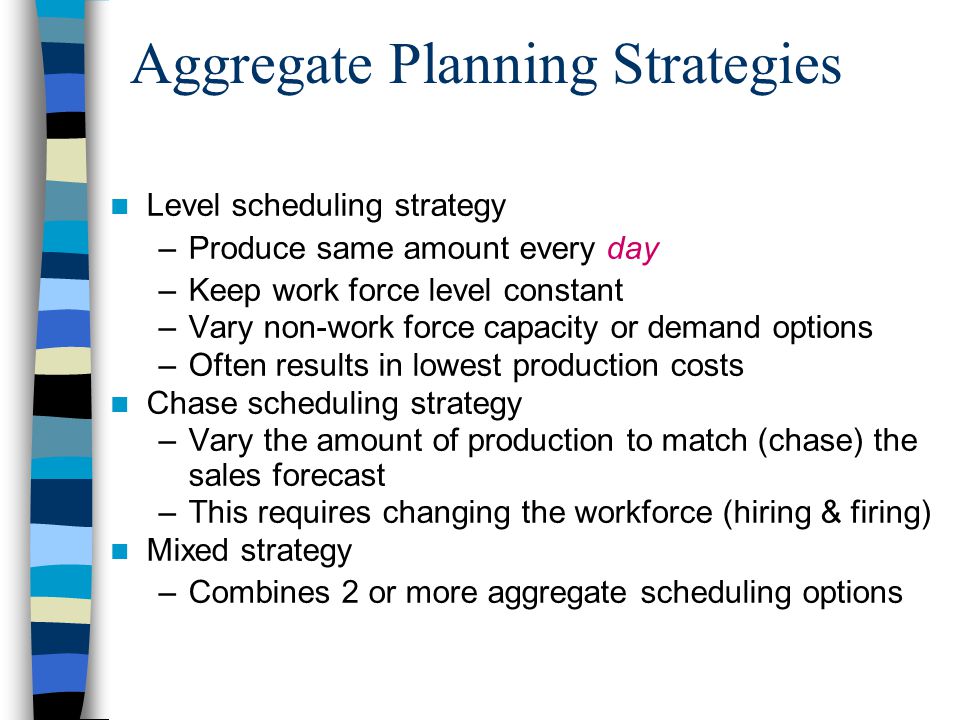

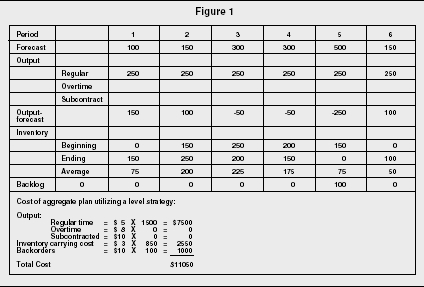

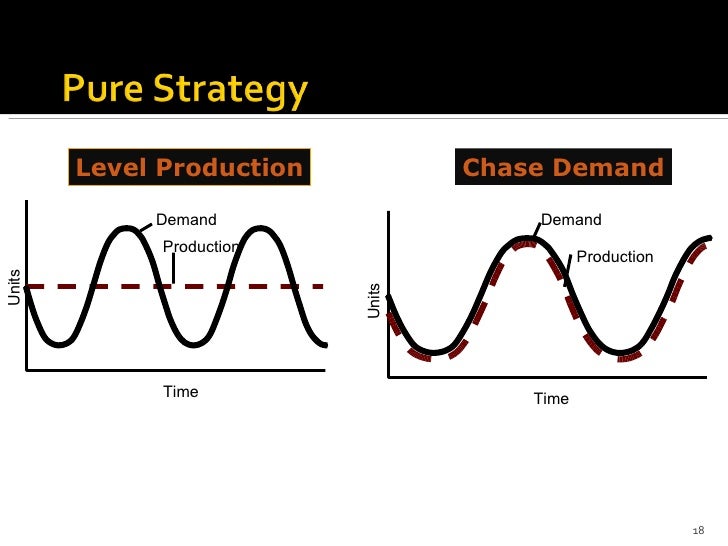

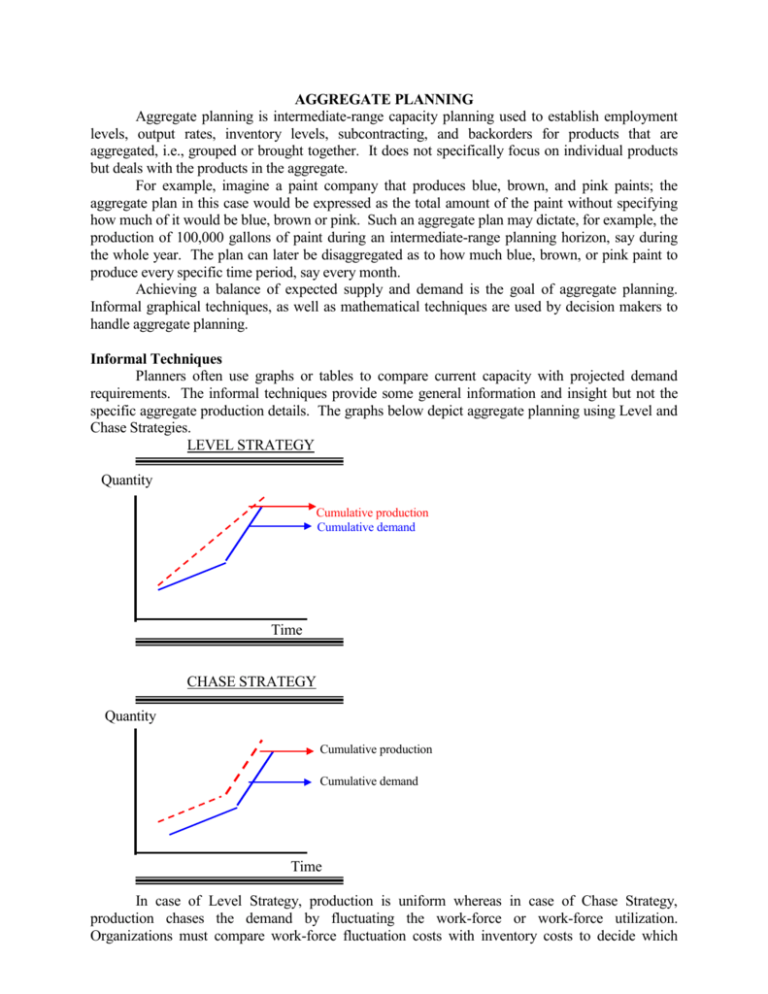

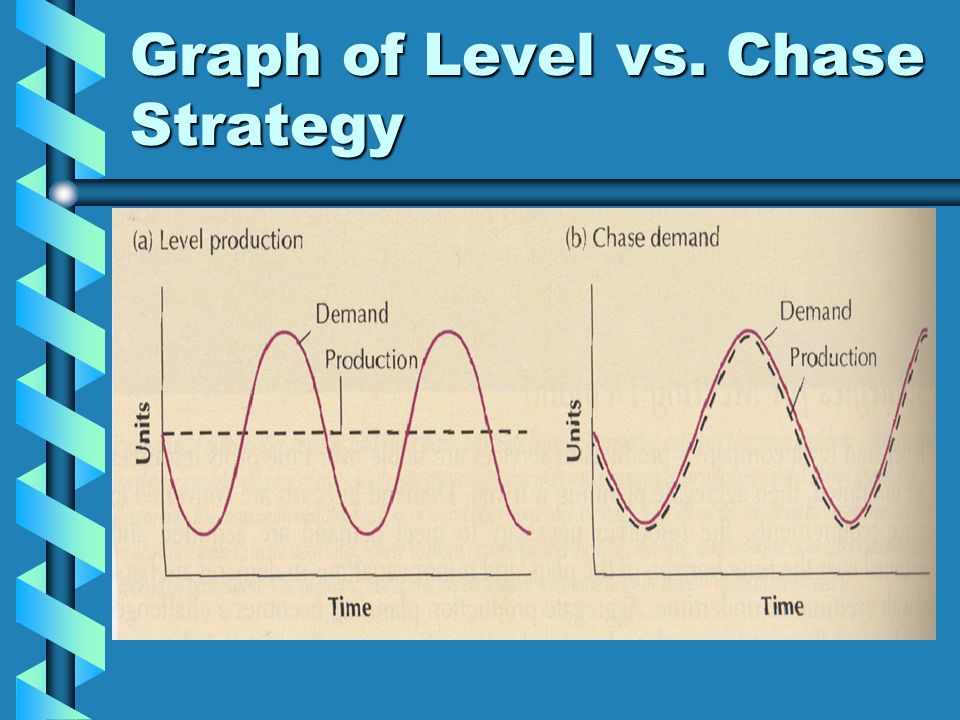

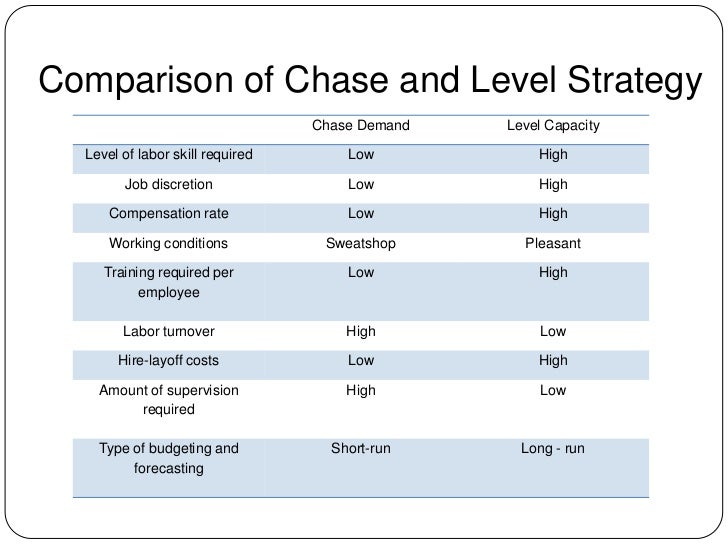

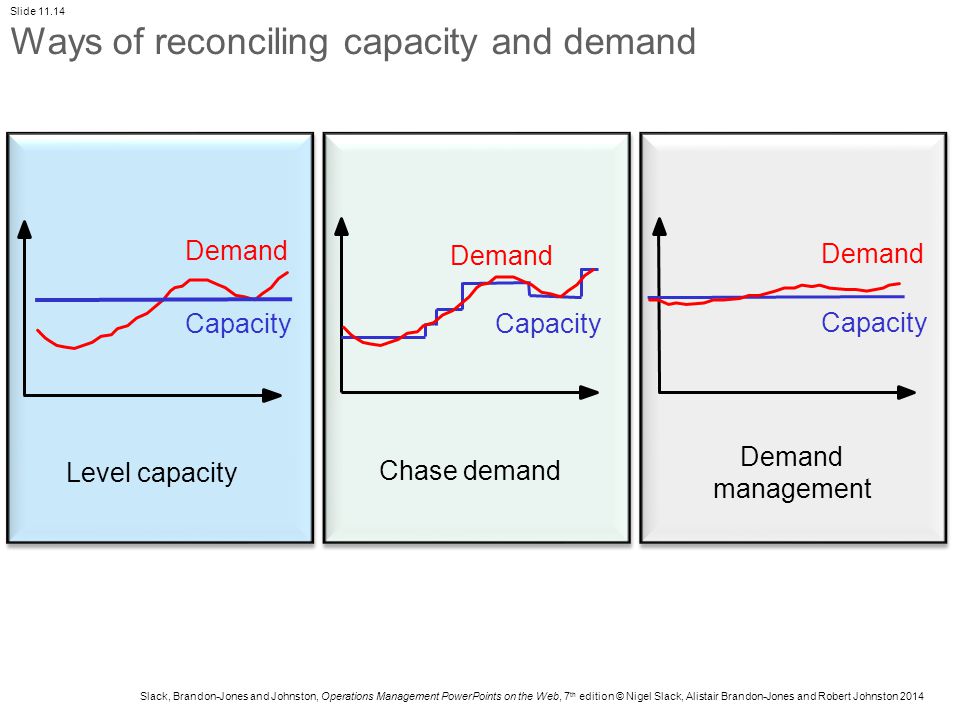

Chase strategy adjusts capacity to match demand Firm hires and lays off workers to match demand Finished goods inventory remains constant It works well for maketoorder firms Level strategy relies on a constant output rate while varying inventory and backlog according to fluctuating demand Firm relies on fluctuating finished goods and • Chase Strategy • Level Strategy • Mixed Strategy 4 5 CHASE STRATEGY A Chase Strategy is a strategy aimed at adjusting capacity in anticipation of demand It is basically "Chasing demand" by doing it dynamically and quickly Demand Units Time Production 5 6 Some of the options available in Chase Strategy • Having part timeNegative results of the level strategy would include the cost of excess inventory, subcontracting or overtime costs, and backorder costs, which typically are the cost of expediting orders and the loss of customer goodwill CHASE STRATEGY A chase strategy implies matching demand and capacity period by period

Push Pull Strategy Wikipedia

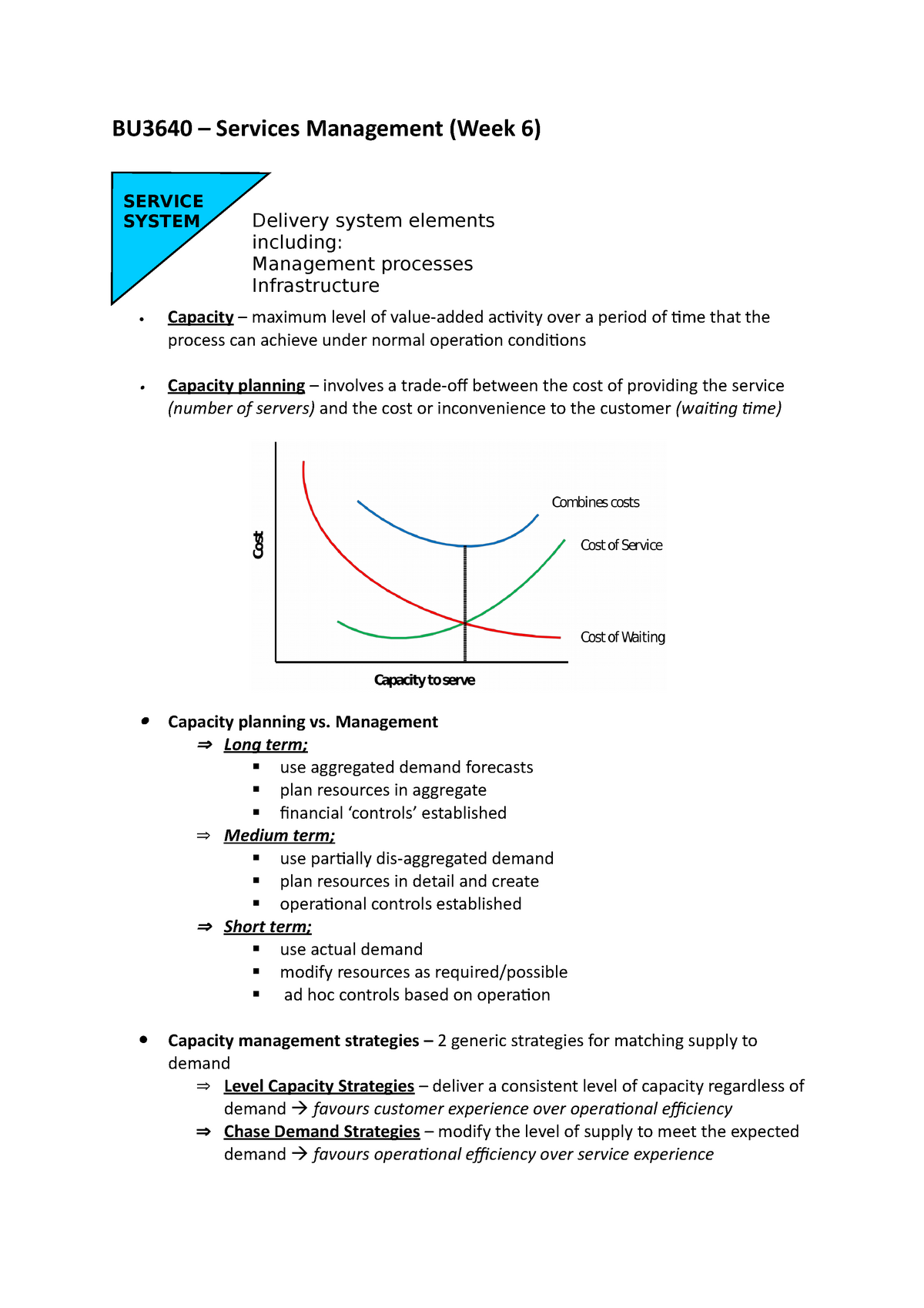

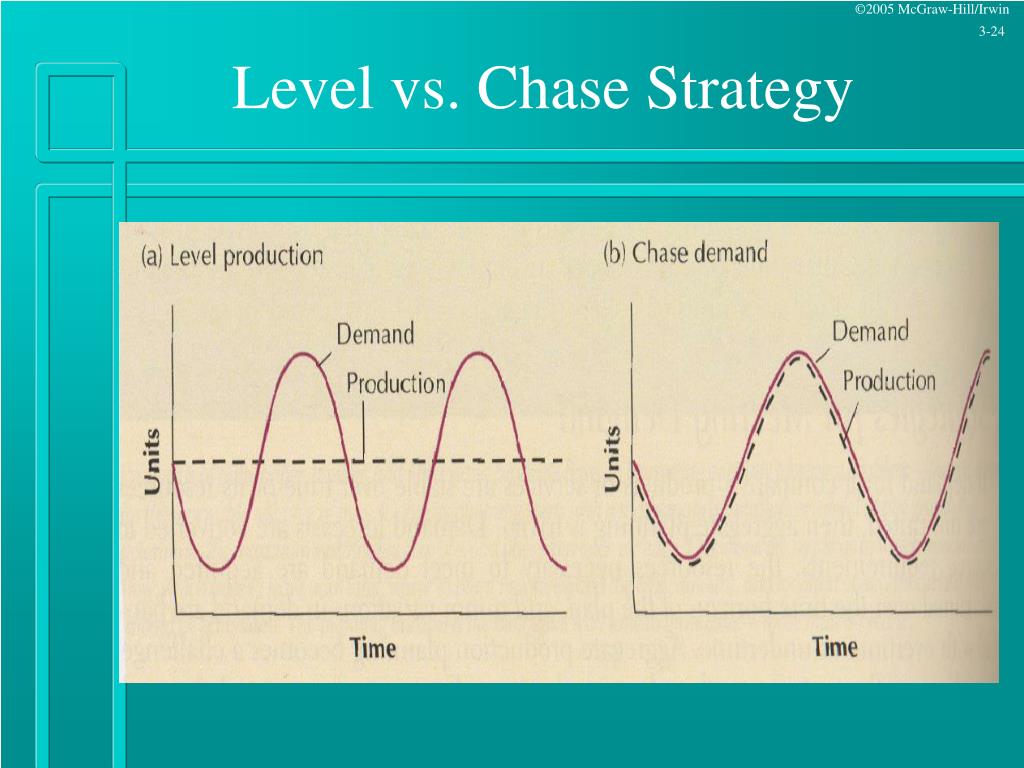

Level capacity strategy vs chase demand strategy

Level capacity strategy vs chase demand strategy-– fast food restaurants Time flexibility from workforce or capacity;Chase (the demand) strategy;

Long Term Capacity Management Linking The Perspectives From Manufacturing Strategy And Sales And Operations Planning Sciencedirect

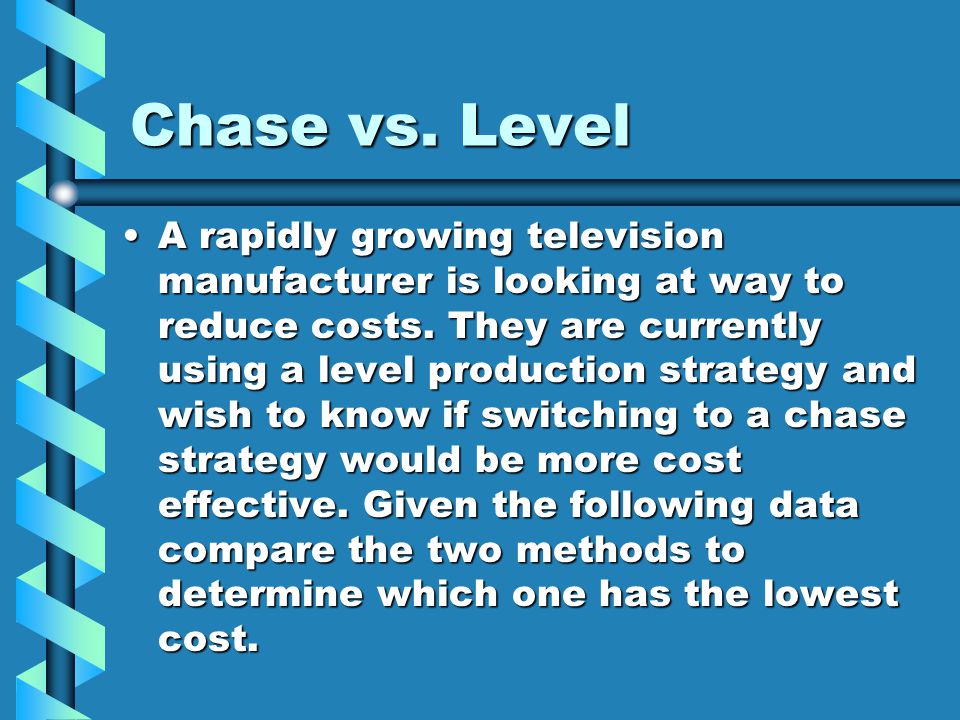

Provide a detailed cost breakdown for using level vs a chase strategy to meet the increased demand Current capacity of 6000 pa Demand of 00 pa Very roughly, a shortfall pa which might be considered a safe level to cover unexpected demandGenerally, these options fall into two "pure strategies which consist of the chase strategy and the level strategy Under the chase strategy, production is varied as demand varies With the level strategy, production remains at a constant level in spite of demand variations The chase strategy, when implemented properly provides a competitive Seasonal Demand One of the most important advantages of a level production schedule is that it keeps the finished product rolling off the assembly line at the same rate throughout the production cycle During periods in which there is a lull in demand for the product, a surplus accumulates, allowing the manufacturer or retailers to store up an

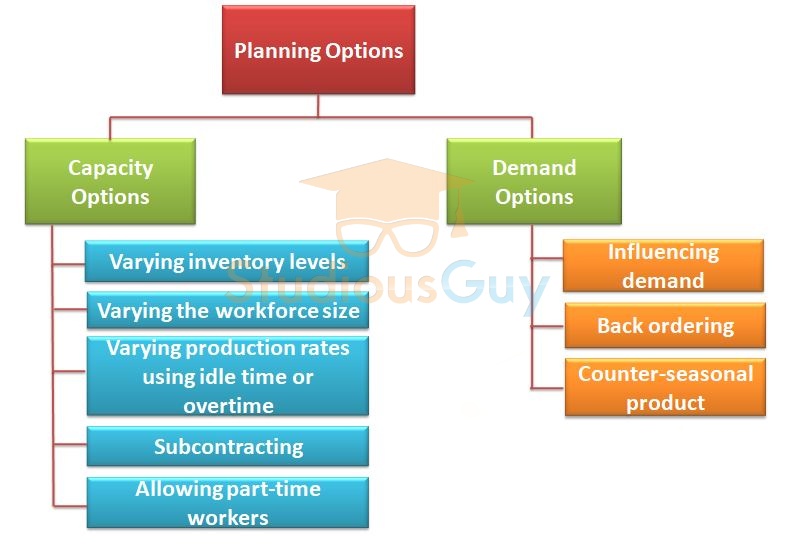

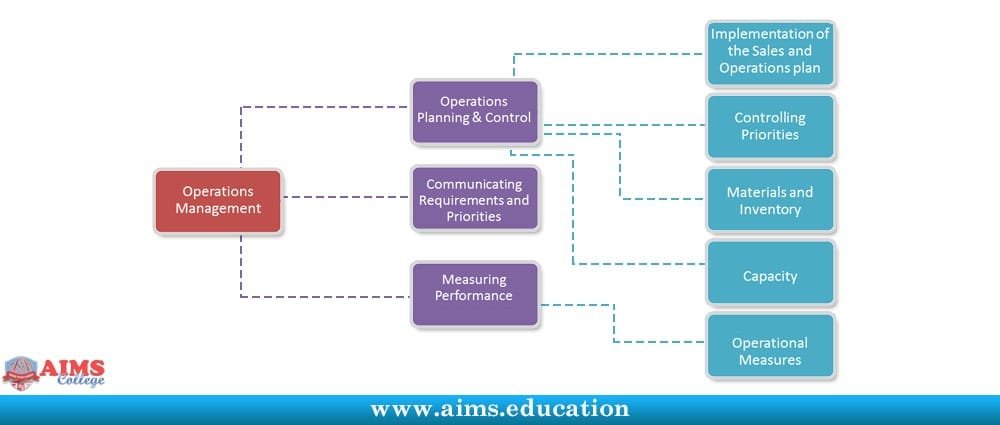

The level of capacity directly relates to the amount of output in the form of goods and services manufacturers can produce to satisfy customer demand Capacity planning strategies can guide manufacturers on how much raw materials, equipment, labor, and investment in facilities need to be acquired over a period of time to meet the future demand over products An essential disadvantage of level strategy is building up inventory costs during the lean period when the demand is low 2 Chase strategy The chase strategy of aggregate planning puts its onus on reducing inventory It keeps pace with demand fluctuations by varying either actual level of output or the workforce numberDemand and Capacity Options Demand Options The four common demand options primarily focus on market aspects apart from backorders which is strictly operational management in nature The operations manager should know all four demand options but should be more interested in back order option 1

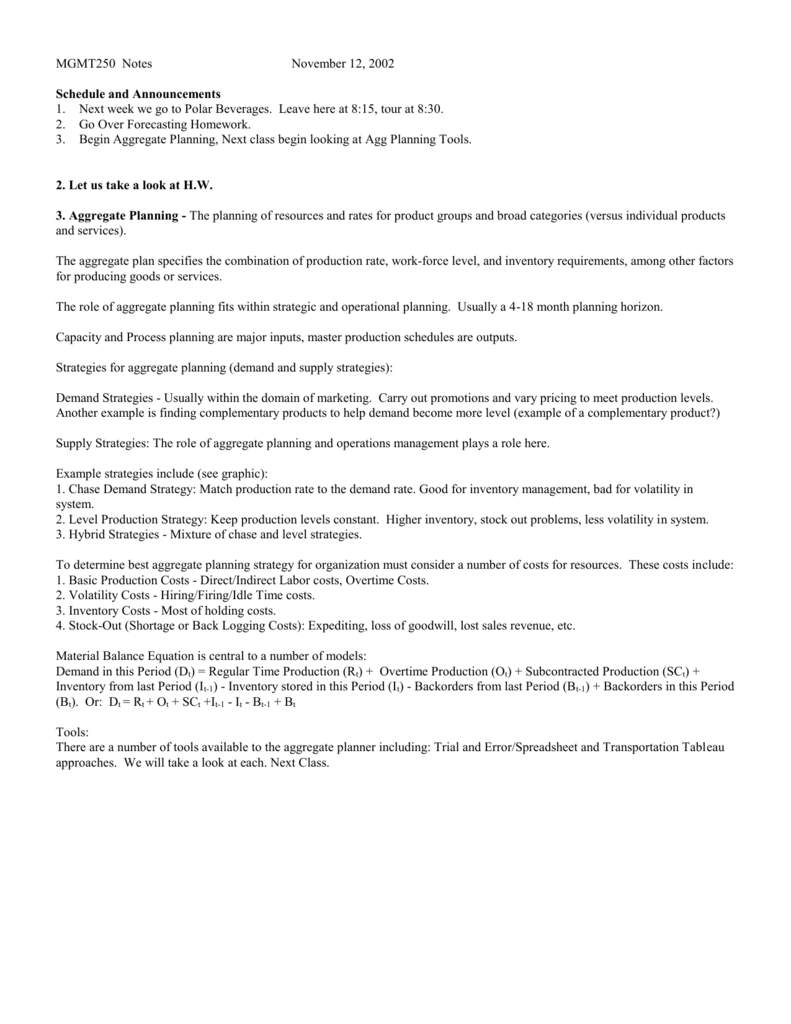

An approach to aggregate planning that attempts to match supply and output with fluctuating demand Depending on the product or service involved, the approach can incur costs by the ineffective use of capacity at periods of low demand, by the need to recruit or lay off staff, by learningcurve effects, and by a possible loss of quality The advantages include low storageA Level strategy B Chase strategy C Subcontracting strategy D Material requirements production strategy E It depends on other factors A A Her e is the forecasted demand for all bearing types Month Demand May 800 Jun 650 JulyQ1 Provide a detailed cost breakdown for using a level vs a chase strategy to meet the increased demand A level strategy produces in a plan that maintains a steady production rate To satisfy demand, the firm must either raise or lower inventory levels in anticipation of increased or decreased levels of forecasted demand Maintaining a level workforce and a steady rate of output when demand

Ppt Chapter 13 Aggregate Planning Powerpoint Presentation Free Download Id

Ppt Planning Demand And Supply In A Supply Chain Powerpoint Presentation Id

In order to use the level capacity strategy, variations in demand are met by A varying output during regular time without changing employment levels B varying output during regular time by changing employment levels C varying output by changing overtime levels D using combination of inventories, overtime, part time, and back ordersIn other words, Manager A is tied to the "chase demand" strategy, and his counterpart, Manager B in the adjacent office, is locked into the "level capacity" strategyAssume 0 units of initial inventory Extra capacity may be obtained by subcontracting at an additional cost of $15 per unit over and above the company's producing them itself on regular time Provide a detailed cost breakdown for using a level vs a chase strategy to meet the increased demand Which strategy do you recommend?

Push Pull Strategy Wikipedia

2

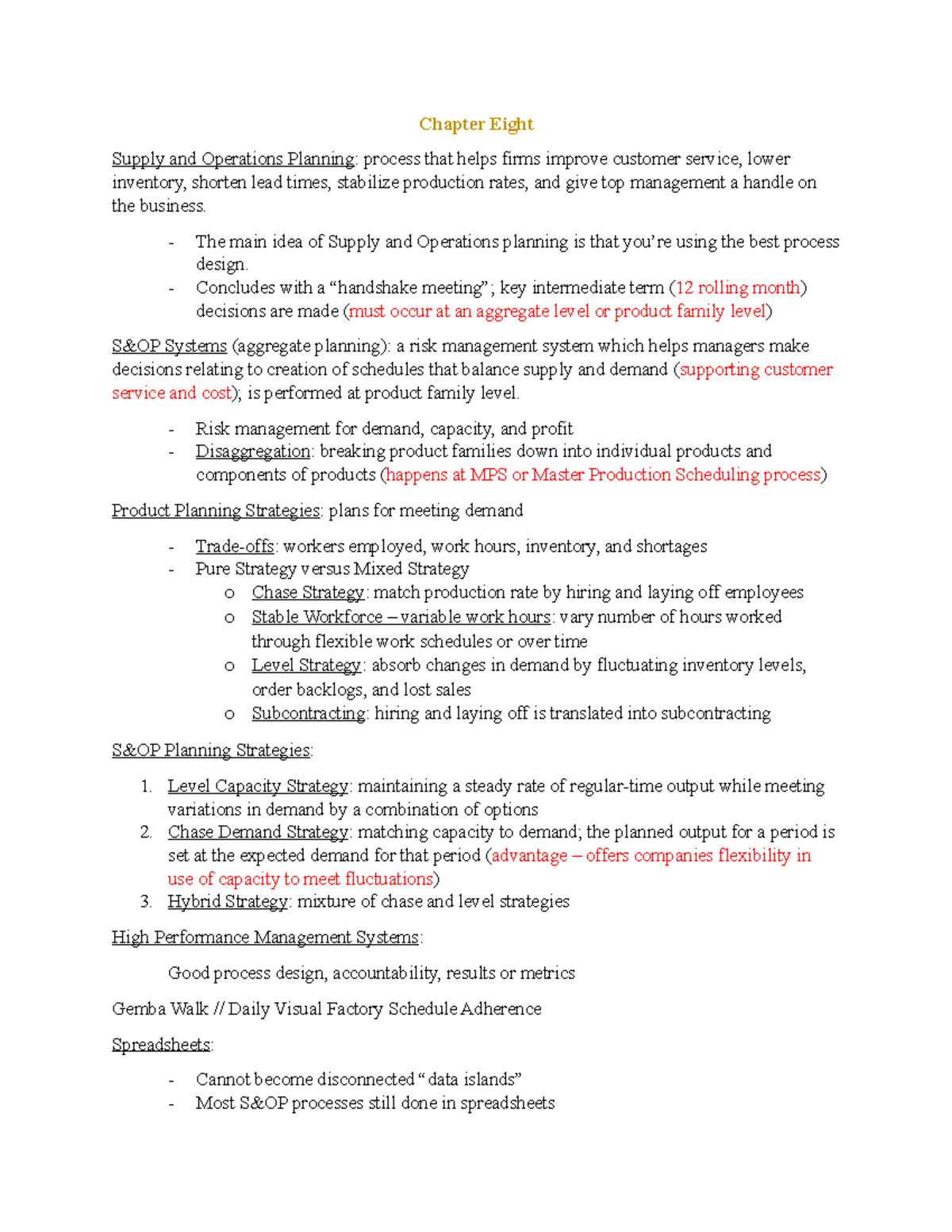

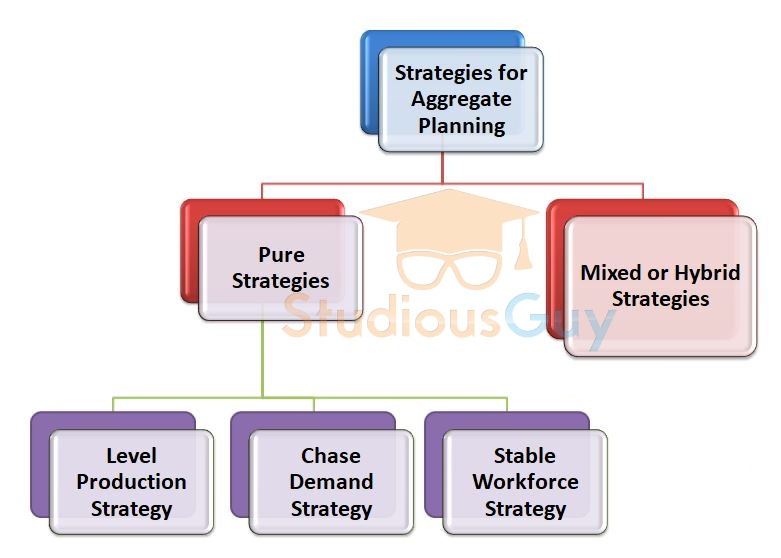

Aggregate capacity is the total amount of capacity required or available to carry out a function It also tells about the 3 best strategies for aggregate planningThey are level strategy, Chase strategy and hybrid strategy Chase strategy is common in companies that don't have a lot of expendable income, a typical small manufacturer, or those that deal in perishable items 4) Infinite Capacity Planning With infinite capacity planning, you attempt to manually match the volume you're able to produce with the demand, so your production line contains no downtimeLevel capacity strategy In this type of strategy, a constant regular time output rate is maintained while meeting the demand variations by a different combination of options b Chase demand strategy In this type of strategy the capacity is matched to the level of demand A period's planned quantity of output is equal to that period's

Complete Guide To Chase Demand Strategy Welp Magazine

1

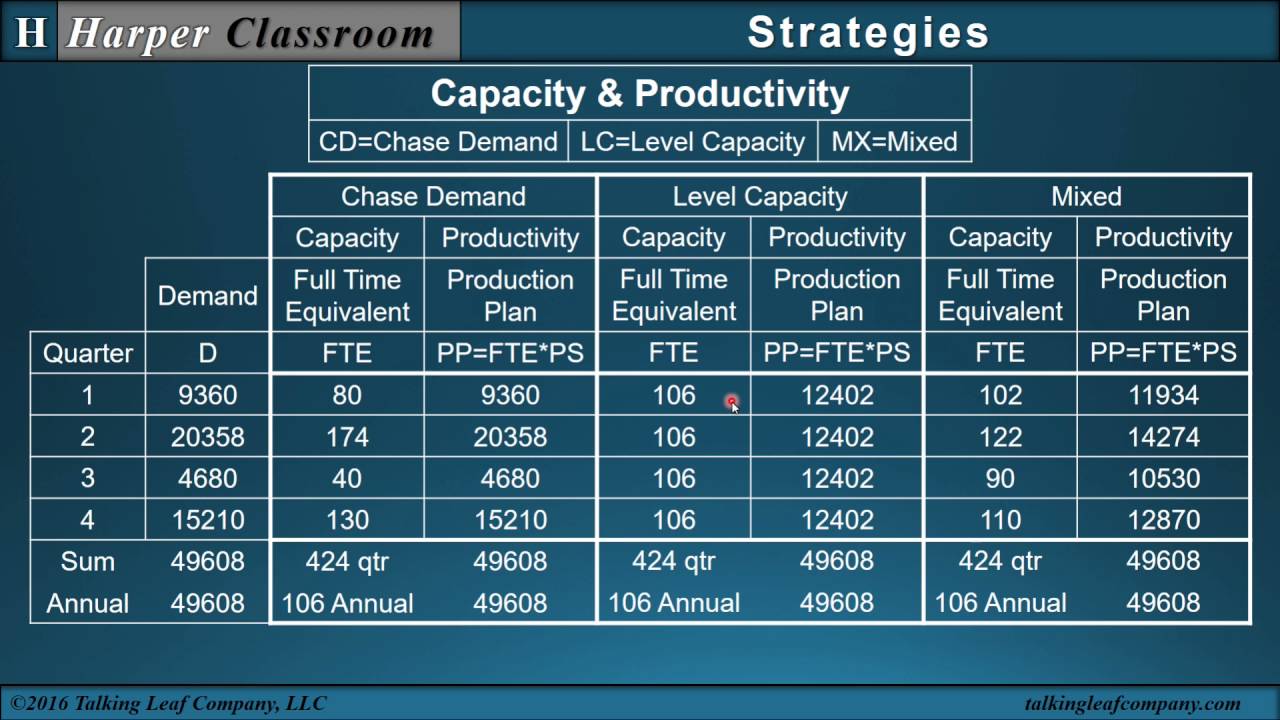

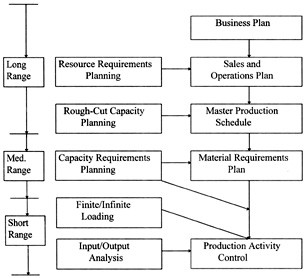

Capacity is the maximum amount of work an accounting practice is capable of completing in a given period of time Capacity planning is the process of determining the resources (time, people, etc) that the firm needs to meet changing demands for its services – in other words, how it will meet its current and future client needsChase Regular time output = Minimum(Forecast, Capacity) Level Required production = Average forecasted demand per period Number of workers = (Required Production/period) / (Production rate/ worker/period) Chapter 12 Material Requirements Planning GR Plannedorder releases of "parents" x No required per unit OR Master Schedule for level zero ANS A level production strategy plans for the same production rate in each time period A chase demand strategy sets the production rate equal to the demand in each time period Subsequently, question is, what types of industries or situations are best suited to the chase strategy the flexibility strategy the level strategy?

2

Capacity Planning 3 Methods How To Implement Them Optimoroute

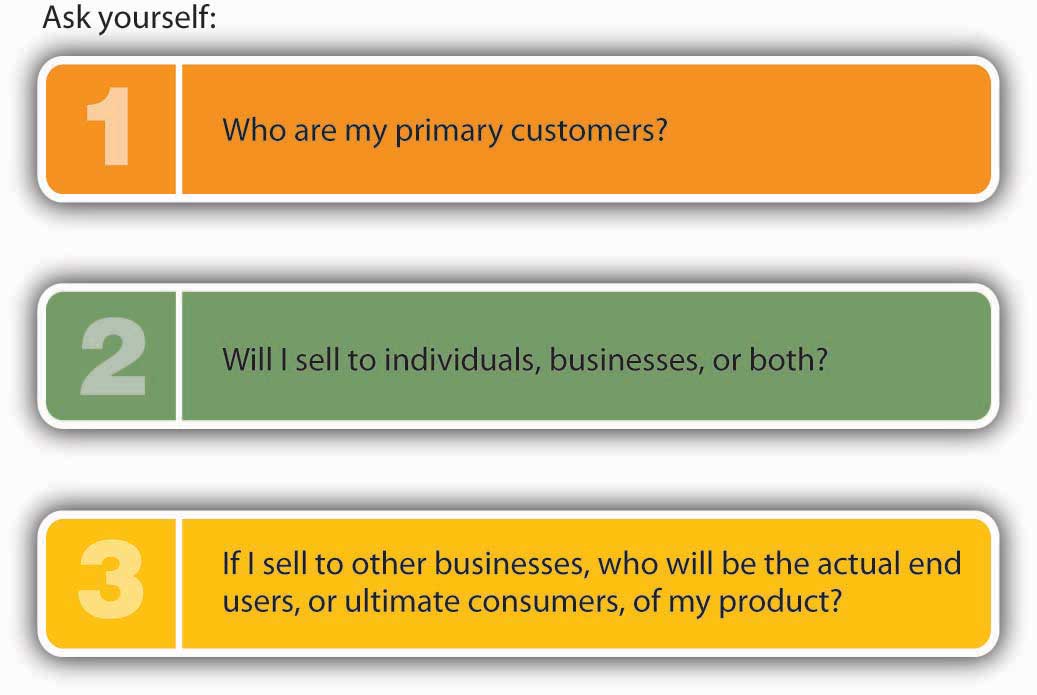

Have to establish a planning strategy which selects the best options A possible way to achieve this is by starting up with both chase and level strategies and then moving later on into a mixed strategy Chase strategy This strategy adjusts production rates to match the demand requirements period by periodSummer, 12,000 Inventory at the beginning of fall is 500 units At the beginning of fall you currently have 30 workers, but you plan to hire temporary workers at theThe strategic business plan is the longterm strategy in terms of revenue, cost and profit objectives Compare and contrast the level and chase aggregate plans These objectives influence the master scheduling decisions in terms of how the demand is satisfied and how capacity is dealt with

Mcq S Week 7 Capacity Management Chapter 8 Week 7 Capacity Management Which Of The Following Studocu

2

This allows the firm to establish higher inventory levels than are currently needed As demand increases, the firm is able to continue a steady production rate/steady employment level, while allowing the inventory surplus to absorb the increased demand 8 9 Chase strategy A chase strategy implies matching demand and capacity period by period This could result in a The chase strategy refers to the notion that you are chasing the demand set by the market Production is set to match demand and doesn't carry any leftover products This is a lean production strategy, saving on costs until the demand – the order – is placed Inventory costs are low, and the cost of goods for products sold is kept to a There are two main aggregate planning methods and strategies the chase strategy and level strategy The chase strategy sets production equal to forecasted demand Many service organizations such as schools, hospitality businesses and hospitals, use the chase strategy The level strategy is mainly focused on maintaining a constant output rate This strategy

Ies 371 Engineering Management Chapter 14 Aggregate Planning Ppt Video Online Download

Demand And Capacity Management Options Adapted From Fitzsimmons And Download Scientific Diagram

The chase strategy is sometimes referred to as demand matching because the strategy varies production to meet demand Benefits The main benefits associated with a chase strategy are lower inventory levels (free capital resources) Reduced carrying costs ;Forecasted demand (Number of parttime workers 6 12 18 15 13 14 Example 1 Level strategy • Each period is hours • From the beginning manager has 10 parttime workers • She wants to minimize undertime in this level strategy • Maximize overtime in order to minimize undertime •There are two pure planning strategies available to the aggregate planner a level strategy and a chase strategy Firms may choose to utilize one of the pure strategies in isolation, or they may opt for a strategy that combines the two LEVEL STRATEGY A level strategy seeks to produce an aggregate plan that maintains a steady production rate and/or a steady employment level In the context of the problem posted by you following the level strategy

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Models Of Aggregate Planning

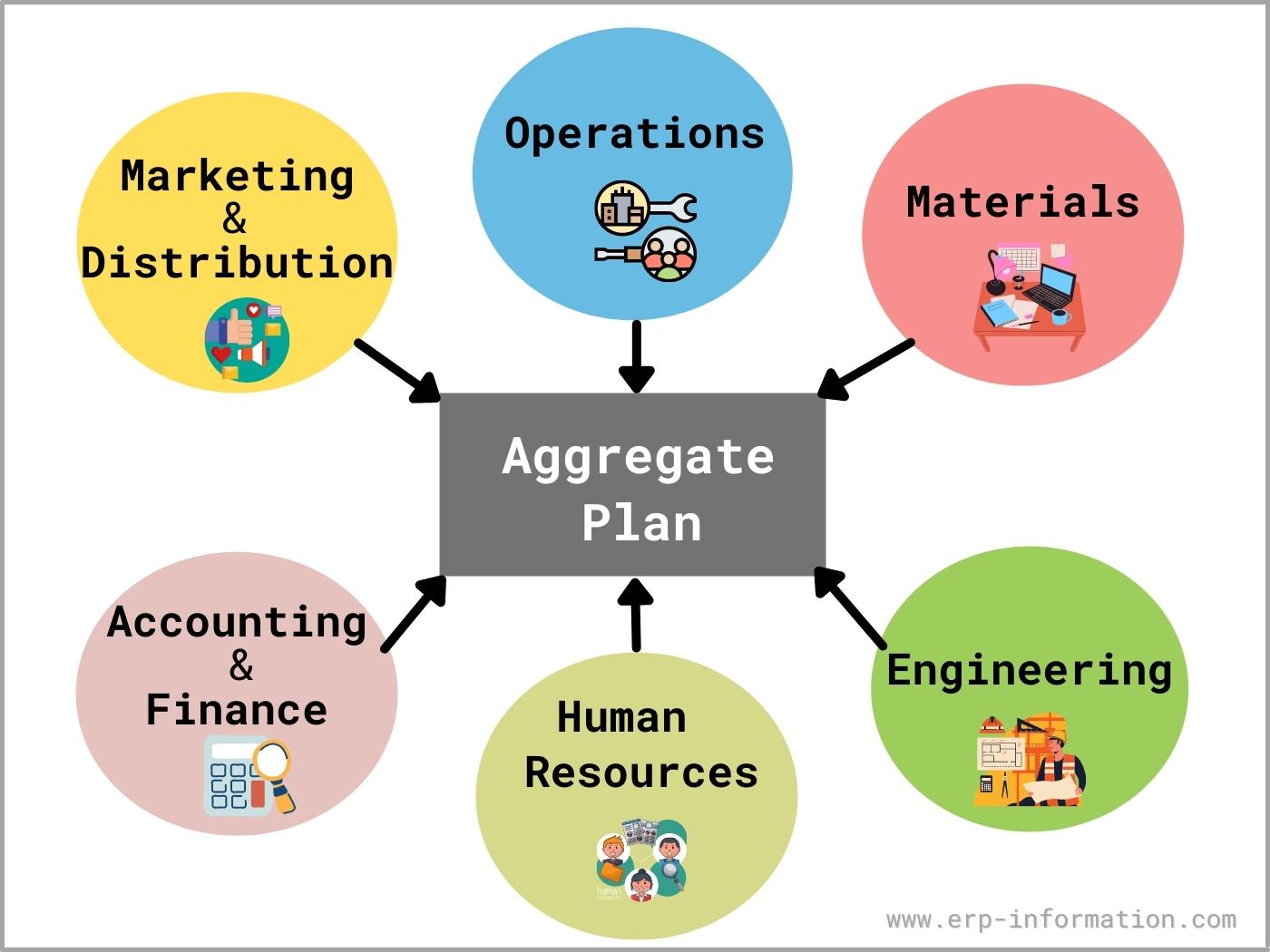

Chase demand strategy is an uncertain demand strategy where the changes made to the output level will depend on the change in the demand In case of chase strategy, the main concern of the management is to respond to the changes in the demand In this strategy, the output changes are carried out following the demand changes in order to save the inventoriesAn aggregate plan gets its name from the fact that it must include demand forecasts, resources and capacity and express these as an aggregate, or combined, strategy This type of planning covers a period of two to 12 months sometimes as much as 18 months, depending on your company's ability to project demand4 Select an appropriate unit of aggregate capacity 5 Determine the relevant cost structures 6 Develop an aggregate planning model Develop alternative aggregate plans and select the best plan Aggregate Planning Strategies Pure chase strategy – match demand period by period Pure level strategy – maintain a level workforce or a steady

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Aggregate Planning Strategies With Excel Dr Harper S Classroom Youtube

When it comes to scheduling your labor force, there are two primary ways to schedule The first is called level scheduling, where you try and maintain a steady workforce with a steady schedule The second is the chase strategy, where you maintain a level workforce and increase your workforce as demand increases Capacity strategy is an approach to increasing and decreasing business capacity to meet demand Capacity includes things like labor and equipment that can be scaled to increase business output The following are common types of capacity strategyCapacity planning is a strategic process whereby a company determines what level of capacity it will need to satisfy the level of demand for its products or services over a period of time Three

Master Production Schedule

Guide To Level Production Strategy Welp Magazine

Strategies in response to uneven market demandmaintain a level workforce,, (LEVEL)maintain a level rate of output (LEVEL)match capacity to demand by time period (CHASE)combination of any of the above (MIXED)– machining shops, army Level strategy;Example When you go to a restaurant for food and place an order the staff will normally pull supplies from a "stable inventory" level and make the order, or in other words "chase the demand"

Chase Demand Strategy Chase Demand Strategy Quarter Spring Summer Fall Winter Sales Forecast 80 000 50 000 1 000 150 000 Production Plan 80 000 Course Hero

A If The Firm Uses A Level Output Strategy Using Chegg Com

Question Calculating level strategy and chase strategy Following is the information about demand forecast and working days for the next six months The work time is 8 hours per day This company does not allow overtime Jan Feb Mar Apr May June Demand forecast 1,440 1,280 1,280 1,9 2,080 1,600 Working days Relevant costWith the chase strategy there are numerous things to reflect on (1) The chase production plan implies that the demand varies (2) Any business that uses this strategy will have to be flexible and be able to change the capacity on a frequent basis (3) The base level of inventory will have to be held at a low level– swim wear 14 Matching the Demand U s e i n v e n t o r y Use delivery time U s e c a p a c i t y Demand Demand Demand 15

2

Demand And Capacity Management Decision Steps Download Scientific Diagram

Chase vs Level Summary To summarize, aggregate planning is a mediumterm operations decision to determine periodic production and inventory levels while resolving the tradeoff between costs of changing capacity and inventoryrelated Costs Chase and Level are two ways to resolve this tradeoff Chase Approach AdvantagesChase Strategy Level Strategy Optimization Develop a production plan and calculate the annual cost for a firm whose demand forecast is fall, 10, 000;

2

1

Demand And Capacity Management Options Adapted From Fitzsimmons And Download Scientific Diagram

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Models Of Aggregate Planning

Operations Management Ppt Video Online Download

Capacity And Aggregate Planning Aggregate Planning The Process

3

Sales And Operations Planning Aggregate Planning Production Planning

2

Pdf Evaluating The Performance Of Aggregate Production Planning Strategies Under Uncertainty In Soft Drink Industry

3 Types Of Capacity Planning Strategies Valq

Pdf Lean Capacity Planning Planning For Maximising Customer Value Semantic Scholar

Bu3640 Services Management Week 6 Bu3640 Services Management Week 6 Service System Studocu

Aggregate Planning Studiousguy

Solved Q1 A1 When Using The Chase Strategy The Total Layoff Chegg Com

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Introduction To Aggregate Planning And The 3 Plans Level And Chase Strategy Included Youtube

2

Match Supply And Demand In Service Industries

Ies 371 Engineering Management Chapter 14 Aggregate Planning Ppt Video Online Download

3 Types Of Capacity Planning Strategies Valq

Chase Method Of Aggregate Planning Ppt Video Online Download

Capacity

Sales And Operations Planning Aggregate Planning Production Planning

Guide To Chase Strategy Production Matches Demand Welp Magazine

Capacity Planning Types Lead Lag Average Strategies Video Lesson Transcript Study Com

Entries For Thursday 25 October 07 Sergio S Blog

Ensuring Capacity Matches Demand Business Govt Nz

Understanding The Effects Of Chasing Demand Vs Capping Your Capacity Dog Trainer S Umbrella

Logistics And Supply Chain Forum Aggregate Production Planning Part I

11 Capacity Planning And Control Operations Management

How Is Yield Management Implemented In Airline Industry Ayat Saleh

Aggregate Planning Strategies Pdf Inventory Economies

Aggregate Production Planning Operations Management Homework And Assignment Help

Aggregate Planning Ppt Download

Aggregate Planning

Pdf Evaluating The Performance Of Aggregate Production Planning Strategies Under Uncertainty In Soft Drink Industry

Chapter Eight Summary Operations Management Chapter Eight Supply And Operations Planning Studocu

Pdf Long Term Capacity Management Linking The Perspectives From Manufacturing Strategy And Sales And Operations Planning Semantic Scholar

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Learning Startegies Chas And Level Production Pdf Inventory Demand

Long Term Capacity Management Linking The Perspectives From Manufacturing Strategy And Sales And Operations Planning Sciencedirect

Aggregate Planning Studiousguy

Chase Method Of Aggregate Planning

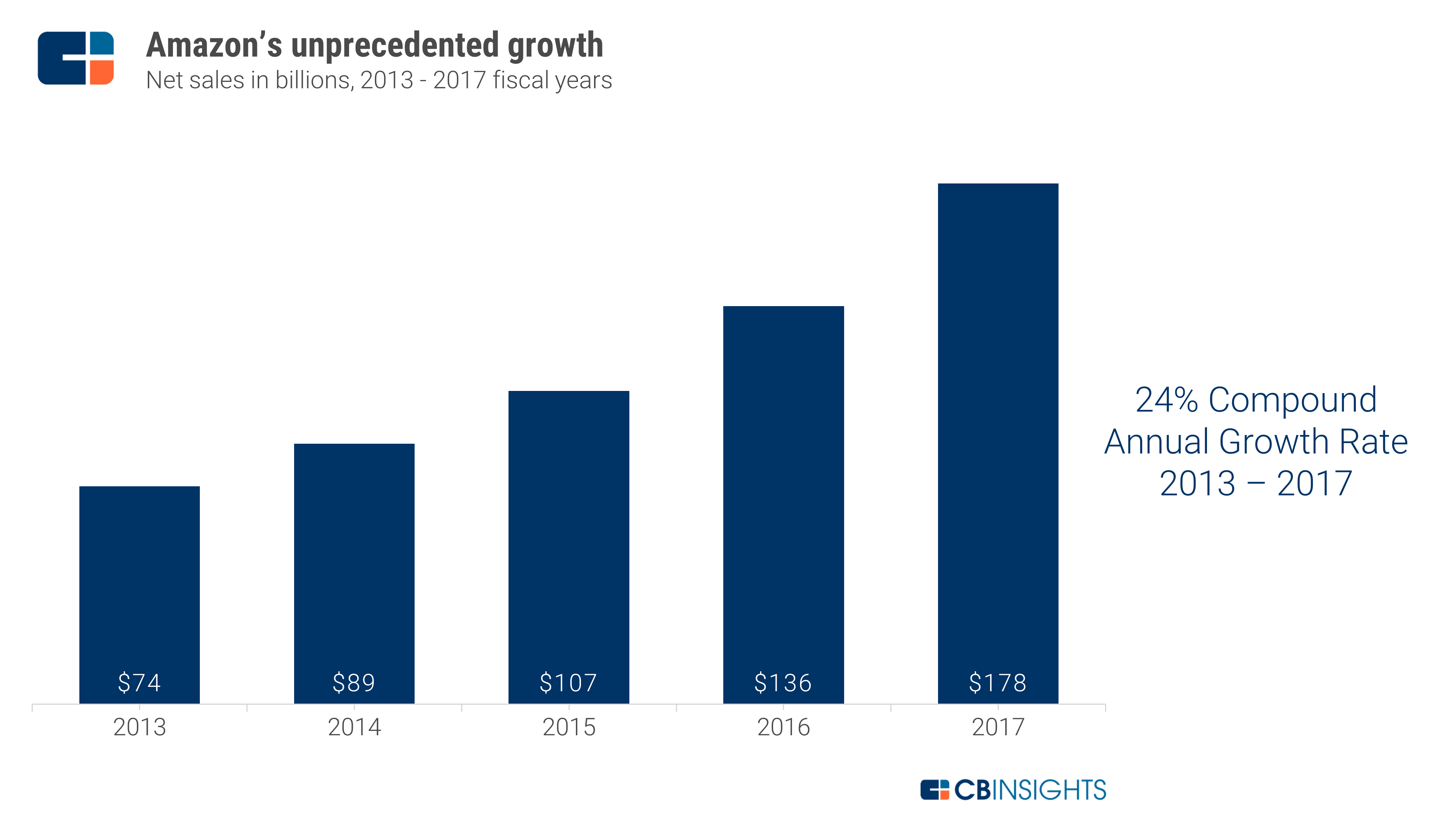

Amazon Strategy Teardown

3 Following Is The Information About Demand Forecast Chegg Com

Demand And Capacity Planning In The Emergency Department How To Do It Emergency Medicine Journal

Logistics And Supply Chain Forum Aggregate Production Planning Part I

Aggregate Planning Studiousguy

Operations Management Aggregate Planning Chapter Ppt Video Online Download

M Dc Operations Strategy

Long Term Capacity Management Linking The Perspectives From Manufacturing Strategy And Sales And Operations Planning Sciencedirect

Om 4600 Notes Week Of September 16 1996

Basic Strategies Level Capacity Strategy Chase Demand Strategy Ppt Download

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Ppt Chapter 3 Aggregate Planning Steven Nahmias Powerpoint Presentation Id

Productionplanning Aggregate Capacity

Aggregate Planning 101 What You Need To Know Brendan Jones

Aggregate Planning

Develop A Chase Strategy And A Level Strategy Using Chegg Com

Aggregate Planning 2 Aggregate Planning Aggregate Planning Intermediaterange

Capacity Planning 3 Methods How To Implement Them Optimoroute

Operations Management Chapter 11 Vocab Review Flashcards Quizlet

Chase Method Of Aggregate Planning Ppt Video Online Download

Aggregate Planning Report

Operations And Supply Chain Management Aims Uk

Aggregate Planning Chapter 11 Aggregate Planning Aggregate Planning

Capacity Planning An Industry Guide Plex Demandcaster

Chapter 11 Capacity Management Ppt Video Online Download

2

Aggregate Capacity Planning Pdf Free Download

Pdfcoffee Com

2

7 1 Capacity Planning Saylor Bus300 Operations Management

Capacity Planningcapacity Planning Long Rangelong Range Springerlink

12 1 Aggregate Planning Operations Management William J

2

Tqm Chapter 11 Assignment Operations Management Tqm Bmc 1101 Studocu

Qdc 1 Supply Chain Flashcards Quizlet

Long Term Capacity Management Linking The Perspectives From Manufacturing Strategy And Sales And Operations Planning Sciencedirect

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

0 件のコメント:

コメントを投稿